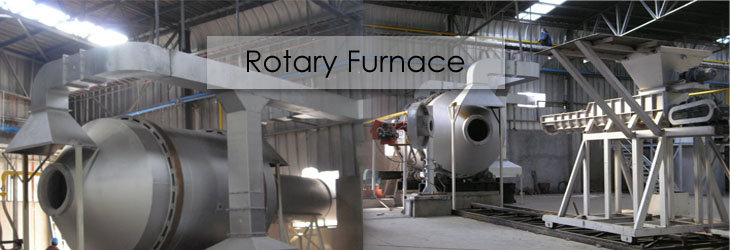

Rotary furnace is designed for treatment and recovery of Lead from Lead Acid Batteries Scrap and for the reduction of Lead Sulphate, Lead Oxides, Lead Concentrates, Lead Dross and Lead Ore. Rotary Furnace will work at temperature of about 1000-1200oC. Thermocouple probe is provided at exhaust duct of the setting chamberfor controlling & maintaining temperature in the furnace.

About Rotary Furnace

The furnace consists of a rotating drum (shell) mounted on a fabricated chassis equipped with a roller drive mechanism. Heat resistant insulation bricks & highly durable refractory lining is fixed at the inner diameter of the shell. The furnace is charged through the open able door called charging door and emptied from two taping ports located at perimeter. Automatic/ manual burner is located on the charging door at the front of the furnace to achieve required furnace temperature. Burner is attached with safety accessories. On the other side of furnace exhaust door is available to carry the flue gases generated from the Rotary furnace which are further processed in pollution control equipment’s as per pollution control norms and finely treated flue gases escape into atmosphere through chimney. Further, the fugitive emissions control system is provided to catch any fumes or flue gases generated during operations from the Rotary ends covering Rotary furnace (including charging port, exhaust port and tapping port) with suitable ID fan, Ducts and Bag House.

The furnace consists of a rotating drum (shell) mounted on a fabricated chassis equipped with a roller drive mechanism. Heat resistant insulation bricks & highly durable refractory lining is fixed at the inner diameter of the shell. The furnace is charged through the open able door called charging door and emptied from two taping ports located at perimeter. Automatic/ manual burner is located on the charging door at the front of the furnace to achieve required furnace temperature. Burner is attached with safety accessories. On the other side of furnace exhaust door is available to carry the flue gases generated from the Rotary furnace which are further processed in pollution control equipment’s as per pollution control norms and finely treated flue gases escape into atmosphere through chimney. Further, the fugitive emissions control system is provided to catch any fumes or flue gases generated during operations from the Rotary ends covering Rotary furnace (including charging port, exhaust port and tapping port) with suitable ID fan, Ducts and Bag House.

The advantages of using the Rotary furnace over conventional methods (say Blast/Fixed Furnace) are as follows:

- Its high production capacity

- Here battery scraps as well as Blast Furnace waste, refining Dross, Bag House powder & Lead Ore too can be processed

- The recovery of Lead is more as compared to Blast/Fixed Furnace.

- This system is environment friendly.

- User friendly with less man power requirement due to less manual work.

| S.no |

Item |

Specification |

| 1 |

Capacity |

20 MT (can be customized based on requirement) |

| 2 |

Burner Type |

Automatic - Gas fired, Oil fired

Manual -

Oil fired, Coal fired |

| 3 |

Raw materials used |

Lead plates, powder and paste |

| 4 |

Fuel Consumption |

Depend on burner and Input Material |

| 5 |

Air pollution control system (APCS) |

Attached to rotary |

| Manpower Required |

| 6 |

Supervisor |

1 Nos. |

| 7 |

Skilled labour |

3 Nos. |

Furnace Charging Machine :

To feed the material into Rotary Furnace a motorized screw conveyor type charging mechanism with Hoper, made by M.S. Plate, with support structure of steel section is provided. To and fro moment of Furnace Charging Machine will be on fabricated Track and driven by electric motor with reduction gear box.

The lead bearing material will be charged into the Hoper of the Furnace Charging Machine with the help of Fork Lift/ EOT/Jib Crane etc.

The furnace consists of a rotating drum (shell) mounted on a fabricated chassis equipped with a roller drive mechanism. Heat resistant insulation bricks & highly durable refractory lining is fixed at the inner diameter of the shell. The furnace is charged through the open able door called charging door and emptied from two taping ports located at perimeter. Automatic/ manual burner is located on the charging door at the front of the furnace to achieve required furnace temperature. Burner is attached with safety accessories. On the other side of furnace exhaust door is available to carry the flue gases generated from the Rotary furnace which are further processed in pollution control equipment’s as per pollution control norms and finely treated flue gases escape into atmosphere through chimney. Further, the fugitive emissions control system is provided to catch any fumes or flue gases generated during operations from the Rotary ends covering Rotary furnace (including charging port, exhaust port and tapping port) with suitable ID fan, Ducts and Bag House.

The furnace consists of a rotating drum (shell) mounted on a fabricated chassis equipped with a roller drive mechanism. Heat resistant insulation bricks & highly durable refractory lining is fixed at the inner diameter of the shell. The furnace is charged through the open able door called charging door and emptied from two taping ports located at perimeter. Automatic/ manual burner is located on the charging door at the front of the furnace to achieve required furnace temperature. Burner is attached with safety accessories. On the other side of furnace exhaust door is available to carry the flue gases generated from the Rotary furnace which are further processed in pollution control equipment’s as per pollution control norms and finely treated flue gases escape into atmosphere through chimney. Further, the fugitive emissions control system is provided to catch any fumes or flue gases generated during operations from the Rotary ends covering Rotary furnace (including charging port, exhaust port and tapping port) with suitable ID fan, Ducts and Bag House.