An Eco-friendly Engineering Solution for Lead

Gravita Group stands for engineering excellence.

Let us help you to invest in sustainable Infrastructure. We have quality, experience and solutions to deliver. Please talk to us

Have Questions?

55+ Turnkey Projects in 40 Countries

Lead Battery Recycling has become an essential part of waste management for any country. Battery recycling by definition is, to reuse/regenerate the materials of a scrap battery by recycling process, that would ordinarily be considered as waste.

Waste management is an important part of the infrastructure as it ensures the protection of the environment and of human health. Waste management is closely related to a number of issues such as process & resource consumption patterns, technology and other socio-economic factors.

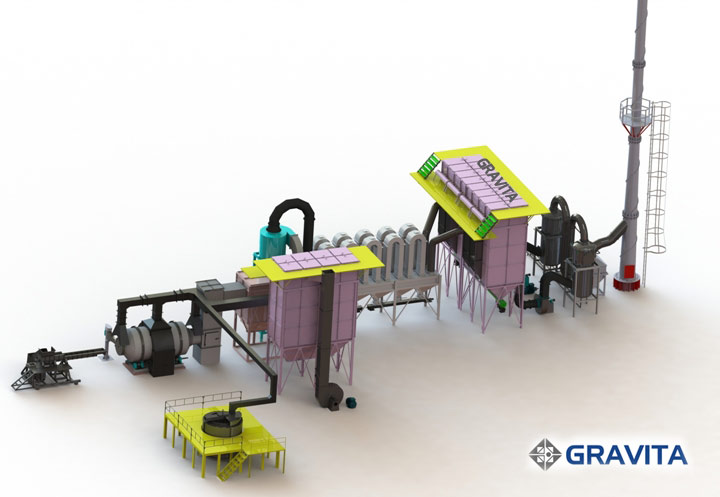

Lead Battery Recycling Plant

- Machinery

- Our Involvement

- Battery Cutting Machine OR Battery Breaking System with Acid Treatment Section.

- Rotary Furnace with Pollution control Equipments, Fugitive Emission Control System & Motorised Charging Machine.

- Lead Refining Furnace.

- Lead Alloying Furnace.

- Fugitive Emission Control System for Refining & Alloying Furnace.

- Ingot casting machine.

- Plastic Crusher

We offer the following services for Lead Battery Recycling Plant

- Plant Layout & Customize Engineering design of the Plant

- Supply of complete Plant & Machinery

- Battery Recycling Process Technology & Technical know-How

- Supervision for Plant Erection & Commissioning

- Training to the personnel’s for Plant efficient plant Operation

- Establish process and product quality

- After Sales Services

- Future business aspect in Lead trade

Lead Battery Recycling Process

The process of the Lead recovery from automotive or industrial scrap batteries for further refining to get minimum 99.97% purity or making Lead alloy or to use in the production of lead oxides or in the casting of grids/terminals to reuse again in the production of lead acid batteries; involving the following basic operations:

- Collection & safe storage of dry / wet scrap batteries

- Battery cutting / crushing & separation of Lead contents / material & other component along with neutralization of acid / electrolyte

- Smelting in closed compact furnace

- Refining & alloying Process

- Pollution control equipments for effective control of the fumes & gases generated during operation of above furnaces

Spent batteries are taken to recycling facilities whereat these are broken down and separated into components to begin the recycling process. The components being separated in the process are; Lead bearing material, plastics and acid which are subject to further recycle/process individually. Recycled Lead is used in all segments of the Lead industry, including battery manufacturing, Lead chemicals, and fabricated products, such as solder for computer circuits, shielding for X-ray machines, Radiation shielding, soundproofing for architecture, and oxides for the glass in computer monitors. Recycled Plastic is used in plastic compounders and fabricators for use in new battery cases and other consumer products. The acid is safely collected in the acid collection tanks for either direct sale or further Neutralization.

Rated

5.0 out of 5.0 for Turnkey projects by 55+ customers on over 40 countries.