|

|

Home > Equipments > Lead Melting Furnace  Request a Quote

Request a Quote

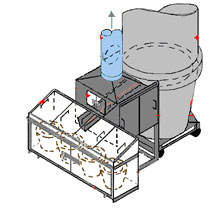

Lead Scrap Melting FurnaceFurnace is a kind of equipment that is used in process of smelting. It is basically used for smelting process. Smelting is a process which involves the reduction of Lead-bearing scrap into metallic Lead in a furnace. The melting furnace has been designed for smelting small size lump scrap of iron, steel, aluminum, any nonferrous metals and waste metal shavings covered with oil or grinding slurry without preliminary cleaning and briquetting. The product of smelting, depending on initial raw material, can be either a branded metal, or an ingot for a further processing. Lead Melting EquipmentsEach furnace is designed and operated to produce a certain Lead product. The following furnaces are the most common types of smelting furnaces used in the industry:

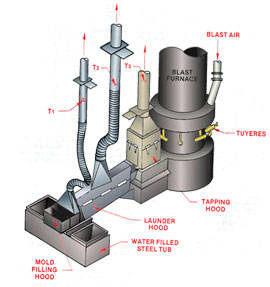

Blast furnaces are designed and operated to produce a hard (high alloy content) Lead product. Blast furnaces emit high levels of Lead fume during the the following processes:

Charging: Emissions may occur at blast furnace feed conveyor transfer points and charging points.Spillage of Lead-containing dust may occur if bucket elevators, conveyors, or skip hoists are overfilled. Lead fume and dust may be emitted from the blast furnace if the charge level is too low. Lead Processing Furnaces

Blast air for the combustion process enters the blast furnace through "tuyeres." The tuyeres occasionally begin to fill with accretions and must be physically punched, usually with a steel rod, to keep them unobstructed. The conventional method used for this task is to remove the cover of the tuyeres and insert the steel rod. After the accretions have been "punched," the cover is replaced. Recently smelters have been able to adapt an "off-the-shelf" automatic tuyere puncher that has greatly reduced employee Lead exposure. However, even with the automatic system there are occasions when the tuyere pipe has to be cleared by using a jackhammer or rod. Reverberatory furnaces are designed and operated to produce a soft, nearly pure Lead product. Reverberatory furnaces emit high levels of Lead fume during the following processes:

Charging

Reverberatory furnace tapping operations involve pouring the molten Lead and slag from the furnace into molds or ladles. Some smelters tap metal directly into a holding kettle, which keeps the metal molten for refining. Other smelters cast the furnace metal into blocks and allow the blocks to solidify.

|

|

Company

|

Blast furnace tapping operations involve removing the slag and then tapping molten Lead from the furnace into molds or ladles. Some smelters tap metal directly into a holding kettle which keeps the metal molten for refining. The other smelters cast the furnace metal into blocks and allow the blocks to solidify.

Blast furnace tapping operations involve removing the slag and then tapping molten Lead from the furnace into molds or ladles. Some smelters tap metal directly into a holding kettle which keeps the metal molten for refining. The other smelters cast the furnace metal into blocks and allow the blocks to solidify.